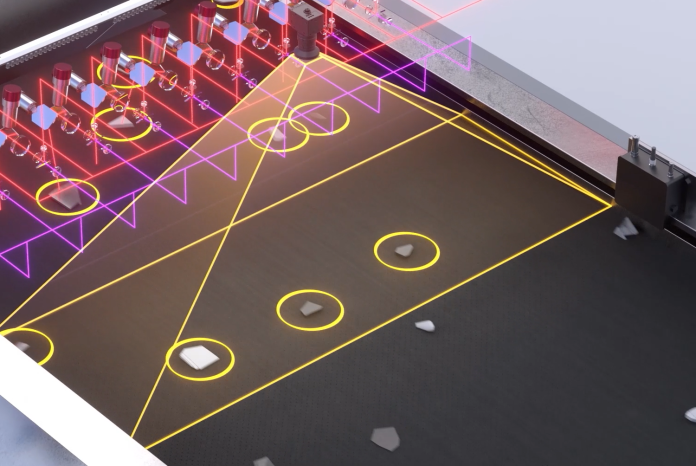

On June 6, 2024, Canon Inc. revealed its plans to introduce cutting-edge plastic sorting equipment featuring innovative material identification technology. The equipment utilizes Raman spectroscopy technology and a tracking mechanism to accurately detect the material types of plastic fragments, even when black plastic pieces are intermixed with other colors—a task that has traditionally posed challenges. The company is now open to receiving orders from the market for the "TR Series," including the "TR-S1510."

Plastic sorting equipment “TR-S1510”

Tracks and measures black plastic pieces on conveyor

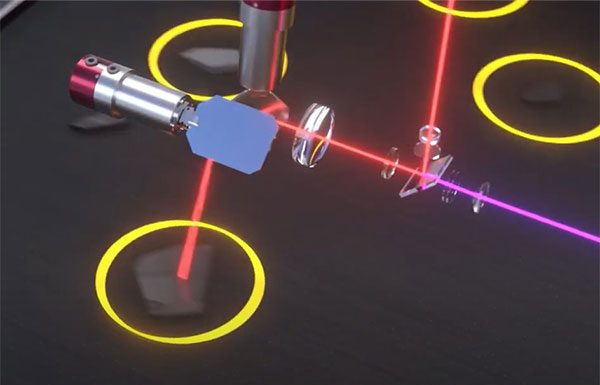

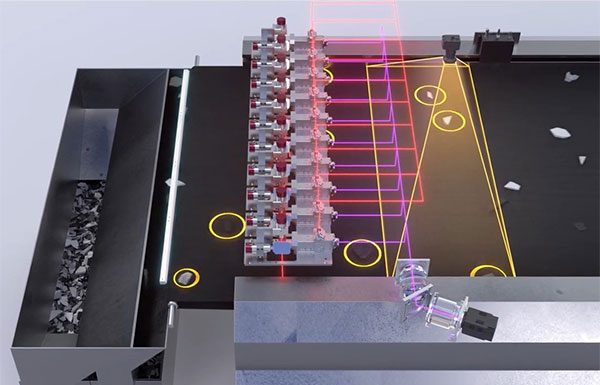

Internal view of equipment

Approximately 20% of plastic waste generated in daily life is currently recycled as material for new products, while the rest is either used as fuel or incinerated. To ensure the purity of recycled plastics, accurate identification of materials like ABS and polypropylene is crucial. However, black plastics, commonly found in home electronics and automobile upholstery, pose a challenge for identification due to their inability to transmit or reflect visible light. Conventional near-infrared spectroscopy struggles with identifying the materials of black plastics. To enhance plastic recycling efficiency, sorting operations require higher accuracy and productivity. Canon's new product utilizes a proprietary tracking Raman spectroscopic method to swiftly sort all plastic pieces, including black ones, with precision, thereby boosting the productivity of recycling facilities. With the introduction of this product, Canon enters the recycling system market with the goal of fostering a circular economy through enhanced material recycling practices.

The exceptional precision and speed of the new product in sorting plastic, including black pieces, can be attributed to its unique integration of Raman spectroscopy with a tracking mechanism. Raman spectroscopy is a detection technique that uses laser light to illuminate plastic pieces, providing molecular information about the substance and enabling material detection. While this method is technically suitable for black plastic, the limited reflection from black plastic pieces results in extended measurement times that do not align with the required speed and throughput for efficient sorting in recycling plants. Consequently, the practical application of Raman spectroscopy for sorting black plastic has been challenging. By combining Raman spectroscopy with Canon's measurement and control equipment, the company has developed a tracking Raman spectroscopy technology that directs laser light towards the pieces, ensuring sufficient measurement time for each plastic piece based on its color. This approach achieves high speed and accuracy overall. With this innovative system, the identification of materials in black plastic pieces, previously difficult with conventional near-infrared methods, can now be accomplished practically even when mixed with other colors. This advancement enhances the productivity of recycling plants, leading to improved material recycling efficiency.

This new product maintains a conveyor speed of 1.5 meters per second and has the capacity to sort up to 1 ton of plastic per hour. Additionally, it offers customization options to match a customer's throughput and installation space requirements by allowing modifications to the tracking and measuring module of plastic pieces or the combination of conveyor belts.

1- According to “Plastic Products, Plastic Waste and Resource Recovery” published by the Plastic Waste Management Institute

2- Acrylonitrile Butadiene Styrene. A type of plastic that is highly resistant to heat and impact.

3- A method of measurement in which an object is illuminated with near-infrared light. Based on such factors as reflection and penetration of light, the object’s light absorption is measured and the type of resin the object comprises can be determined

4- By continuously moving the position of the laser, the target object is continuously illuminated by the laser, allowing for light to be reflected