Japanese researchers have developed an innovative method for producing polymers. This new combination technique is expected to significantly advance the field of plastics. We can look forward to the emergence of more eco-friendly, heat-resistant, and transparent plastic materials.

Background Information

A research team led by Professor Masami Kamigaito and Lecturer Mineto Uchiyama from the Graduate School of Engineering at Nagoya University, along with Professor Kotaro Sato from the Tokyo Institute of Technology, has built upon the work of Nobel laureate Giulio Natta in the field of polymers. Natta's technique, known as asymmetric cationic polymerization, which dates back to the 1960s, facilitated the creation of polymers but did not allow for the control of their molecular weight. The molecular weight of polymers is crucial, as a higher molecular weight results in tougher and more durable materials. In essence, molecular weight is a key factor in plastic engineering, influencing the properties and performance of plastic materials.

About The Novel Technique

The research team in Japan has achieved a significant scientific breakthrough by successfully controlling the molecular weight of polymers. Their success stems from the integration of two techniques: their own living cationic polymerization and Natta’s asymmetric cationic polymerization. This advancement allows for precise control over molecular weight and enhances optical activity, resulting in the production of polymers that exhibit greater resistance to chemical and environmental destruction are produced.

The Starting Point of Experimenting

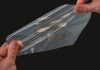

The researchers began experimenting with benzofuran, a compound known for its unique properties. Benzofuran not only originates from natural resources but also serves as a precursor to the polymer polybenzofuran, which shows great promise as an alternative material in plastics. Regarding its characteristics, benzofuran is chemically recyclable and can produce rigid polymers due to its high glass transition temperature. Consequently, the polymer derived from benzofuran is capable of withstanding extreme temperatures while maintaining its solid form. In summary, benzofuran is considered a valuable compound for the production of sustainable transparent thermoplastics.

Outlook: A Wide Range of Applications

The innovative polymerization method developed by the researchers can effectively stabilize the molecular weight and optical activity of polybenzofuran, paving the way for the creation of new functional polymer materials. Lecturer Uchiyama is optimistic about polybenzofuran serving as an alternative to the widely used polystyrene, which is commonly found in everyday products like plastic containers, cases, and packaging. Polybenzofuran shares a similar structure with polystyrene but holds significant promise as a future alternative for packaging materials. Additionally, Mr. Uchiyama asserts that polybenzofuran possesses further advantages, which may enhance its applicability and sustainability in various industries.

"While polybenzofuran is not yet commercially available as a plastic, it features a stiffer molecular structure and a higher glass transition temperature compared to polystyrene. This positions it as a promising candidate for a new type of plastic with excellent thermal properties. Additionally, its unique optical characteristics could provide extra functionalities, enhancing its potential applications in various fields."