Smart fabrics are currently very popular, with companies globally working on creating jerseys that have built-in sensors and bike shirts that come with GPS capabilities. One particular area that is showing significant promise is printed electronics. For instance, Wearable Life Science is seeking out companies that have the ability to print conductive and washable materials onto fabrics.

Smart fabrics are currently a popular trend, with companies globally working on creating jerseys that have integrated sensors and bike shirts with GPS functionality. Market research firm Gartner forecasts that smart shirts will be the next big thing in the lifestyle and fitness market, similar to how activity tracking bracelets were popular this year, as reported in an article by The Guardian.

According to Gartner, sales of smart clothing are projected to increase from nearly non-existent to over 10 million in 2015 and are expected to reach 26 million in 2016. Currently, brands such as Adidas, AiQ, Underarmour, and Ralph Lauren have introduced smart shirts designed for elite athletes and early adopters. Experts anticipate that sportswear featuring integrated electronics will soon become essential for weekend warriors and individuals focused on health and fitness.

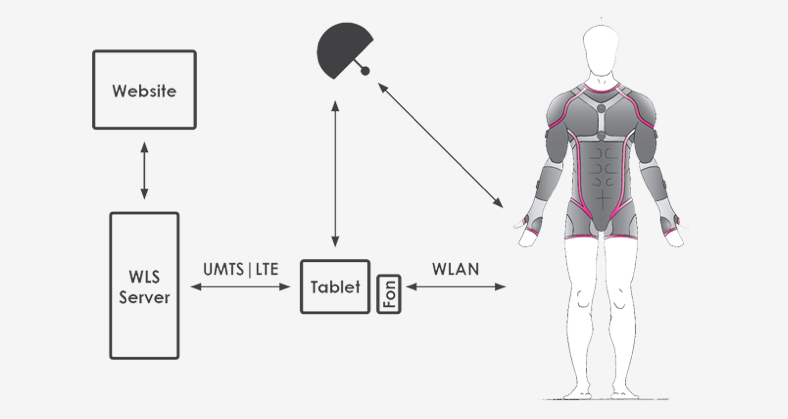

Wearable Life Sciences, a German start-up, is targeting the smart clothing market with its Antelope suit, which recently received the ISPO Brandnew award for being the top newcomer in the active wear segment. Unlike many smart garments that primarily measure biological data such as heart rate, body temperature, and sleep cycles, the Antelope suit serves as a training device in itself. Kay Rathschlag, the founder of WLS, elaborates that the suit's integrated electrodes enhance the natural muscle contractions during workouts, thereby increasing the effectiveness of every exercise session.

An electronic steering unit, approximately the size of a smartphone, is operated through an app to activate the electrodes and regulate the intensity of the impulse. The technology of the suit is founded on the principle of electrical muscle stimulation (EMS), a method that has been utilized and researched in fields like rehabilitation, physiotherapy, and training for elite athletes. The suit is engineered to amplify the training benefits of athletic pursuits like running and cycling. With sensors and electrodes seamlessly integrated into the suit, EMS training can now be conducted outdoors for nearly any activity.

Wearable Life Science is initiating a Kickstarter campaign to progress the technology from prototype to production. Although the foundational components are established, there are still tasks to complete. Rathschlag identifies printed electronics as a promising area for development. He and his team are seeking companies capable of printing conductive materials onto fabrics. The primary challenge lies in ensuring that the conductivity is sufficiently high to deliver electrical impulses at the desired strength.

Moreover, the printed electronic ink must possess qualities such as washability, stretchability, durability, and comfort for wearers. Wearable Life Science has engaged in discussions with multiple companies that have the potential to produce a product meeting the desired quality standards. However, Rathschlag has not yet finalized a decision on a supplier. Nevertheless, it is highly probable that printed electronics will be incorporated into the design. Rathschlag mentioned that wires printed with conductive ink would be the simplest and most preferred option, while also exploring the use of conductive yarns and other materials.

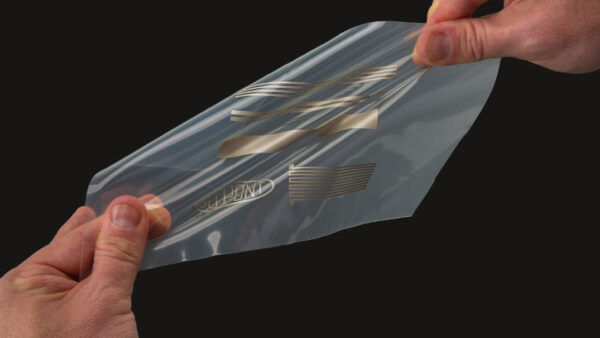

Major corporations are highly attuned to the potential in the smart clothing market. DuPont Microcircuit Materials has created stretchable conductive inks and materials that can be incorporated into smart apparel. Presently, a silver-based conductive ink is already on the market, with additional inks and sensors in the development phase. DuPont states that these new materials offer a resilient, comfortable, flexible, cost-effective, and production-ready option compared to electronically conductive yarns, polymers, and other materials.

DuPont's inks are utilized on thin thermoplastic polyurethane (TPU) film, which is subsequently laminated onto the fabric. DuPont states that the material maintains strong performance even after 100 wash cycles. This marks a significant advancement for smart clothing, but ink developers, textile printers, and sportswear manufacturers are all collaborating on new products and processes that can push the boundaries further. In the near future, smart clothing may become as ubiquitous as sports watches.