Linx Printing Technologies has unveiled two new inks specifically formulated to tackle the challenges of printing consistently high-quality and easily readable codes on the latest generation of flexible films.

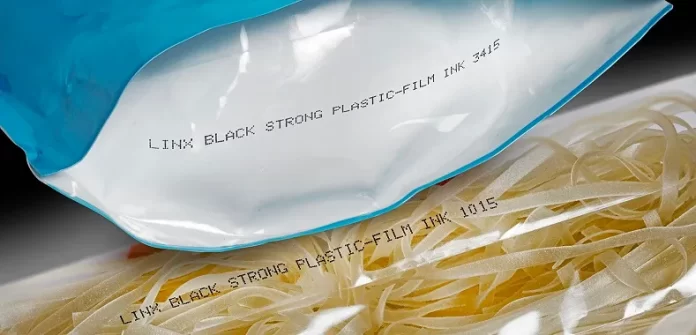

Linx Black Strong Plastic-Film Ink 1015 and Linx Black Strong Plastic-Film Ink 3415 have been specifically developed to meet global customer demands for inks that provide reliable code adhesion on plastic film packaging. These inks are well-suited for various packaging formats, including plastic flow wrap for dry foods and plastic pouches for food sauces, confectionery, pet foods, and household chemicals.

“Legislative changes, including new plastic taxes, along with increasing demands from retailers and consumers, are prompting manufacturers to reduce their plastic usage. This shift has resulted in a transition towards stronger laminated plastic films and a greater emphasis on recycled and recyclable packaging,” stated Simon Millett, Inks Product Manager at Linx Printing Technologies.

“As a result, we are witnessing the emergence of thin flexible plastic wrapping and pouches made from OPP, BOPP, HDPE, and LDPE. However, these materials can pose challenges for ink adhesion, as many general-purpose inks do not adhere effectively to these lower surface energy plastics. This can lead to issues such as smudging, scratching, or codes rubbing off during production or transit, potentially resulting in rework, product rejects, and even fines,” explained Simon Millett.

The two new inks have been specifically designed to deliver excellent adhesion while ensuring readability and supporting printer reliability. Both inks are free from PFAS (per- and polyfluoroalkyl substances) and CMR (carcinogenic, mutagenic, reprotoxic) substances, and they comply with the EuPIA (European Printing Ink Association) Exclusion Policy. Notably, Linx Black Strong Plastic-Film Ink 3415 is a non-MEK formulation, further enhancing its suitability for various applications.

To guarantee the inks' suitability for the global market, Linx conducted extensive testing on packaging formats from various countries, including Australia, China, France, the UK, India, the Philippines, and Poland. This comprehensive approach ensures that the inks meet diverse regional requirements and perform effectively across different applications.

“Our team of scientists designed and tested over 100 formulations during the development process to ensure we created a truly versatile solution suitable for a wide range of pack types and applications,” stated Dr. Amy Ruddlesden, Ink Development Manager and Principal Chemist at Linx Printing Technologies.

“The new Linx Black Strong Plastic-Film Inks 1015 and 3415 will assist customers in achieving full traceability for their products by providing consistent, high-quality, and easy-to-read codes on today’s flexible plastic packaging,” emphasized a representative from Linx Printing Technologies.